Micro-atomizzatore privo di aerosol

Micro-atomizzatore privo di aerosol

Il sistema VarioSpray HP atomizza senza problemi piccoli volumi di sostanze ad alta viscosità. La portata è regolata indipendentemente dalla pressione del liquido mediante la modulazione della larghezza dell’impulso, dove l’angolo di spruzzo e la dimensione della gocciolina rimangono costanti. L’ugello è utilizzato in una vasta gamma di applicazioni nell’industria alimentare. VarioSpray HP rende i processi di produzione più economici limitando al solo ingresso del liquido evitando i sistemi a doppio fluido (aria-acqua) più complessi.

Gli ugelli pneumatici tradizionali sono normalmente usati per umidificare pezzi di pasta, spruzzare olio vegetale sui prodotti o applicare agenti distaccanti per migliorare la qualità delle superfici. Questi ugelli sono molto adatti per spruzzare fluidi viscosi e sono stati l’ugello di prima scelta in passato per l’applicazione di piccoli volumi di liquido in combinazione con aria compressa. Tuttavia, questi ugelli non sono affatto la soluzione ideale da un punto di vista economico. Non appena l’aria è coinvolta nella tecnologia di atomizzazione, è impossibile evitare la formazione di aerosol. In molti casi, ciò significa che è necessario incapsulare il modulo spray e installare sistemi di estrazione complessi e costosi. La quantità di perdita di materiale, i costi per la pulizia e la manutenzione e l’inevitabile contaminazione dell’ambiente circostante l’installazione, nonché gli effetti negativi sulla salute dei dipendenti si rivelano dubbi quando si tratta delle prestazioni complessive di queste installazioni.

Atomizzazione senza aria compressa

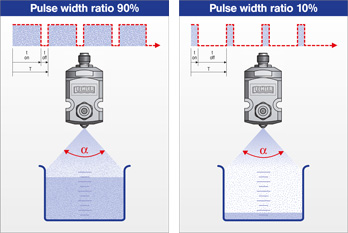

Lechler ha sviluppato una nuova soluzione. Lo sviluppo del sistema VarioSpray HP è un’estensione dell’originale VarioSpray II. Entrambi sono ugelli a fluido singolo, che non richiedono aria compressa. Rispetto a VarioSpray II, VarioSpray HP può atomizzare in modo affidabile piccoli volumi anche con liquidi a viscosità più elevata (fino a 75 mPas). Questo è realizzato tecnicamente con il metodo di modulazione dell’ampiezza dell’impulso. Ciò comporta la variazione dei tempi di accensione e spegnimento di un segnale lasciando inalterata la frequenza. La portata (fino a 1 l / min a 3 bar) è determinata dal rapporto larghezza impulso. È quindi indipendente dalla pressione e consente la realizzazione di angoli di spruzzatura costanti e dimensioni delle gocce uniformi. I parametri rilevanti per la qualità rimangono costanti durante l’intero processo.

I prodotti o gli oggetti che vengono trasportati su nastro velocità diverse possono essere bagnati in modo molto preciso con la quantità desiderata di fluido di atomizzazione.

Spraying liquids variable and precise

Aerosol-free micro-atomizer

The VarioSpray HP nozzle valve system atomizes very small volumes of high viscosity substances without any problems. The flow rate is regulated independently of the liquid pressure by means of pulse-width modulation, where the spray angle and droplet size remain constant. The nozzle is used in a wide range of applications in the food industry. VarioSpray HP makes production processes more economical by dispensing that use sparse amounts of spray media with complex twin-fluid systems.

Traditional pneumatic atomizing nozzles are normally used to humidify pieces of dough, spray vegetable oil on products or apply release agents in order to improve the quality of surfaces. These nozzles are very suitable for spraying viscous media and have been the first-choice nozzle in the past for applying small volumes of liquid in combination with compressed air. However, these nozzles are by no means the ideal solution from an economic point of view. As soon as air is involved in atomization technology, it is impossible to avoid the formation of aerosol. In many cases, this means that it is necessary to encapsulate the spray module and install complex and expensive extraction systems. The amount of material loss, costs for cleaning and maintenance, and unavoidable contamination of the installation surroundings, as well as negative effects on the health of employees proves to be doubtful when it comes to the overall performance of these installations.

Atomization without compressed air

Lechler has developed a new solution. The development of the VarioSpray HP nozzle valve system is an extension of the original VarioSpray II. Both are single-fluid nozzles, which do not require compressed air. In comparison with the VarioSpray II, VarioSpray HP can reliably atomize very small volumes even with higher-viscosity liquids (up to 75 mPas). This is realized technically by pulse-width modulation method. This involves varying the on and off times of a signal while leaving the frequency unchanged. The flow rate (up to 1 l/min at 3 bar) is determined by the pulse width ratio. It is therefore independent of pressure and permits realization of constant spray angles and uniform droplet sizes. Quality-relevant parameters remain constant throughout the entire process.

Products or objects which are transported on a belt at different speeds can be wetted very precisely with the desired quantity of atomizing fluid.

Optimized flow rates and the omission of expensive compressed air systems save on material and money while increasing the economic efficiency of installations. In addition to the costs of lost fluid, the costs for installation cleaning and operating costs for extraction equipment are saved. Flexible and high belt speeds are possible with clock frequencies up to 200 Hz. The continuously variable flow rate with a turn-down ratio of 29:1 and flexible adaptation of the spray quantity to different requirements allow fast and efficient production with minimum conversion and product change times. This makes installation concepts even more productive. Since the flow rate is no longer controlled by pressure, the omission of corresponding systems means that it is possible to realize shorter installation times and reduce the amount of maintenance required, resulting in lower operating costs. A system without the formation of aerosol has positive effects on the cleanliness of the workplace and protects the health of employees.

Soiling of the nozzle valve can be removed completely by backflushing with up to 40 bar allowing it to be free of residue. This eliminates the need for complex and time-consuming disassembly of the spray unit. The peak-&-hold control function keeps heat development in the valve at a low level and therefore saves energy compared with traditional valves. VarioSpray HP is made entirely of high-quality stainless steel and is therefore suitable and approved for use in the food industry.

Simple integration

The nozzle valve system can be integrated in both existing and new installations quickly and easily. VarioSpray HP offers maximum flexibility for users. The system is completely modular, so that the compressed air-free nozzle can be adapted flexibly for individual requirements. The product range is designed exactly to meet the needs of individual applications. In addition to valves and hoses, it also includes two control variants (Smart for max. 8 valves, Flex for max. 16 valves) as well as modular spray headers.

The predefined control concepts from Lechler allow most atomization requirements to be realized after only a very short installation and start-up phase. The sales consultants from Lechler are available to provide individual advice and customized concepts. Overall, VarioSpray HP is an atomization system that guarantees the highest quality and makes installations more productive, simpler and cleaner. At the same time, the system reduces investment costs and makes it possible to achieve a fast return-on-investment.