As a global supplier, Cama Group knows that there are two primary elements to any successful machine order. Technology and people!

As a global supplier, Cama Group knows that there are two primary elements to any successful machine order. Technology and people!

Simply delivering powerful yet easy-to-use machines and helping companies to modernise their infrastructure – especially in emerging and growing markets – is just half the story. Understanding local customs, cultures and business practices is just as vital!

A case in point is a recent project, which saw Cama deliver three secondary packaging machines to a confectionery manufacturer in Middle East. Cama is fortunate to have a team that has been working with the region for a number of years. “We have a sales and engineering team that is used to the market dynamics and the ways of doing business. I particularly enjoy working in this region, as it is all down to gaining confidence and building close and very open and honest relationships”.

The market itself is also in a state of flux, seeing rapid expansion of existing home-grown companies and huge investment from many leading multi-nationals looking to gain share. The influx of global companies is forcing many local companies to “up their game” in terms of packaging, to at least match the shelf appeal and larger-scale economies of foreign companies.

The Middle East region is rapidly evolving, especially over the last five years, and is becoming highly influenced by global trends. In fact, the Middle East is rising as one of the fastest-growing markets. While some countries in the region are facing economic instability, the market still offers low taxation compared to the European market.

The Middle East, as an emerging market, is less concerned with specifications and instead is interested more in machine suppliers that offer high standards in terms of people, technology and machine building.

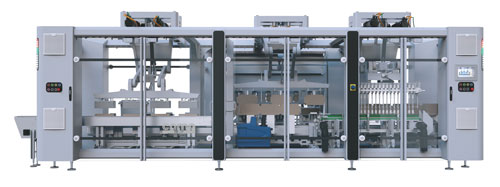

Cama’s Breakthrough Generation (BTG) comprise modular, scalable frameworks that offer easy entry and access, coupled to a hygienic machine design. Within this framework, contemporary automation solutions, including advanced rotary and linear servo technology, is tightly coupled to in-house-developed robotics, to deliver the all-important flexibility and adaptability required by modern packaging operations.

Servo technology is used throughout the machine, which is what gives it its excellent flexibility for format and packaging-count changes. The robot solution used has been developed in house by Cama, which means it can deliver perfect robot/machine synergy. Cama is unique in the market in this respect. By removing third-party robotic controllers, Cama can also sidestep any potential communication conflicts that can affect output. The robot technology has been specifically perceived for secondary packaging applications and, due to this in-house development, when Cama technicians install the machines or troubleshoot any issues, they are 100% capable of servicing the robot technology, too.

Cama’s customer recognized that the design of the machines and the know-how that they got from the project team was also a major feature that any technical team will be looking for.

www.camagroup.com