With a start in the textile field and thanks to years of experience and know-how, Color Service introduced its unique technology into many markets segments (rubber, tire, cosmetics, plastics) before orienting its innovation into the food industry, where the dosing of powders and liquids requires considerable precision, speed and traceability.

With a start in the textile field and thanks to years of experience and know-how, Color Service introduced its unique technology into many markets segments (rubber, tire, cosmetics, plastics) before orienting its innovation into the food industry, where the dosing of powders and liquids requires considerable precision, speed and traceability.

Why dosing is so important in food processing?

Weighing is a key element of the food production process for quality compliance: dosing the proper amount of ingredients is extremely important to fulfil recipe specifications and constant quality requirements.

In most cases, the food industry’s weighing department employs operators who manually dose raw ingredients, resulting in difficult and complicated management in terms of weighing accuracy.

To support this necessity, Color Service technology is designed to solve problems associated with the manual weighing of any kind of powders and liquids applied in the food industry and it is developed with the goal of achieving a safe, fast and precise dosing. The aim is therefore the development of high-efficiency systems that allow to minimize the production costs and boost productivity while also improving final product quality, essential for the competition of all companies.

According to customer’s requirements, Color Sevice offers to the market two solutions of automation: a complete fully automatic and a semi-automatic weighing system.

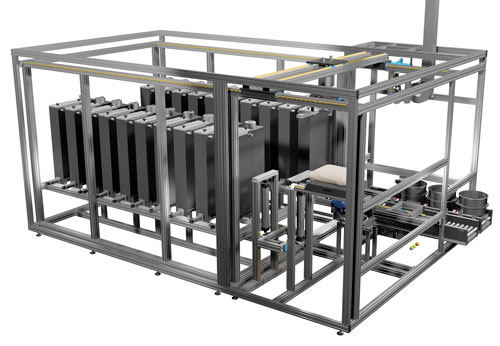

With the fully automatic dosing system, all processes are automatically monitored and data are recorded in the software integrated with the customer’s management system. The activity of the operator is exclusively confined in the loading of products into storage silos of various capacities through high-performance vacuum for powders and pump for liquids that guarantee fast loading with low air consumption.

During the dosing, a multi-scale conveyor completely aspirated through a dedicated dust extraction system allows high dosing accuracy of recipes that can be dosed directly into a bucket or in identified bags created in a completely automatic way: this is a fundamental characteristic that allows each individual recipe to be traced. The fully automatic system guarantees high dosing accuracy, batch traceability and modularity of storage stations and according to product consumption and production requirements, the system offers several storage modules of different capacities that could be interchangeable or expanded in the future.

Semi-automatic dosing system

On the other hand, the semi-automatic weighing system can offer a good compromise: the robotic storage of powder products with the manual weighing assisted by a PC. In this way, according to the recipe, the system drops the right box and transfer it to the weighing position, where the operator, guided by the PC can dose the product.

Key benefits of Color Service automatic dispensing system

By investing in an automatic dosing system, the customer will be able to benefit from a repeatable production process that runs 24 hours a day, is reliable and fast, in which human error is definitively eliminated and which allows leading to high-quality end products with uniformity features throughout time.

Systems are user-friendly and software is intuitive and easy to use, allowing a quick and easy understanding. “Dosing right the first time” as a consequence of accurate and exact dosing of powders and liquids, results in a reduction of product waste, energy/water consumption, processing times and, as a consequence, cost.

From the ecological point of view, Color Service technology reduces to zero the exposure for operators to dangerous substances or toxic ingredients and provides absolute control of the dust emitted during the weighing with the use of special suction devices, ensuring total operator safety and environmental protection.

Another significant advantage is the traceability of recipes. Indeed, with a manual weighing, in case of non-conformity, it is impossible to identify all the products that are affected by this problem downstream and it is difficult to trace the causes upstream that can be represented for example by an incorrect mixing proportion or from a non-conformity of a specific ingredient. Without expensive labour costs due to manual batch processing and profit loss due to recipe formulation mistakes, companies can begin to boost profits, while offering a superior and uniform product to their customers.