The DMC company was founded in 2001 and for the first few years the main activity was represented by mechanical processing for third parties, then the Labelling division was created, dedicated to the design and construction of labelling machines for the food and beverage sectors.

The DMC company was founded in 2001 and for the first few years the main activity was represented by mechanical processing for third parties, then the Labelling division was created, dedicated to the design and construction of labelling machines for the food and beverage sectors.

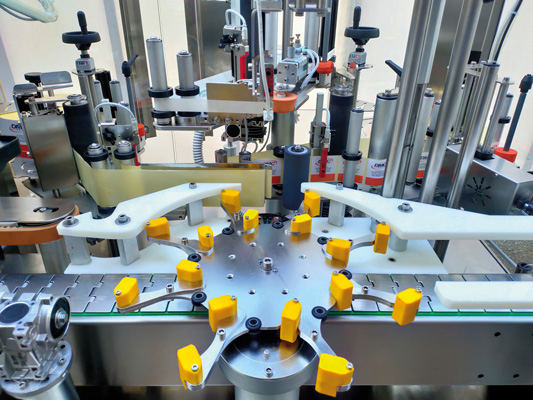

All the machines are characterized by an innovative labelling system based on the use of the container rotating plate. This application guarantees the labeller considerable versatility of use and high precision in the finishing of the package, as well as a simple and economical format change. All models are highly customizable, thanks to the possibility of integrating several functional groups, even designed ad hoc, to meet specific packaging requests. Therefor not only reliable and performing machines but also machines built to fit customer’s needs: he can count on a real 360° technical consultancy service in the development of the project of his own customized machine.

The products by DMC are innovative, by choice. In fact, several patents have been filed relating to the study and design of high-performance and cutting-edge labelling systems, relating to both bench labelling machines and automatic line equipment. Recently, solutions and strategies have been adopted within the workplace to aim at the efficient use of energy, the development of sustainable mobility and the reduction of consumption and waste, combining profit with environmental protection and growth of a green sensitivity in all the company staff. At the same time, a digital transformation process has started thanks to the adoption of solutions for document archiving and the introduction of new tools and procedures in the production department for the computerized management of orders and of the warehouse.

Today, the range of products by DMC includes innovative labelling machines with hourly production between 500 and 4000 bph and includes both bench models and semi-automatic and automatic line models. The flagship model among manual labelling machines is the ALPHA PRO, a bench machine suitable for the packaging of multiple types of containers, from cylindrical to conical, square and shaped, which guarantees high labelling precision and a quick and economical format change thanks to the use of the rotating plate system. This labelling machine is also designed for the application of a neck label or a small medal, allowing the packaging of the classic sparkling wine bottle to be carried out with manual bench equipment. Among the automatic models, the SONIC stands out, an automatic 4000 bph labelling machine: it is a linear machine suitable for the packaging of cylindrical formats, which uses an innovative labelling system (patent pending) by means of opposing rollers which makes this model a valid alternative to traditional vacuum-type labelling machines. The range in 2022 has been enriched by a new labeller, the MHIRA model that will be presented at the SIMEI fair in Milan from 15 to 18 November 2022. This is the classic 1500 bph linear labeller for packaging the Bordeaux bottle, which however stands out for various technical features that make it a product that is certainly out of the standard. In fact, the machine uses the system of three labelling rollers but combines this module with a new unit for moving the capsule smoothing column, which allows to obtain an optimal finish, both with the rolling machine and with the thermal head, even at speed of 1500 bph. The screw feeder is universal and does not need to be replaced if multiple formats are used, furthermore the labelling stations are equipped as standard with an angular adjustment mechanism that allows you to work even with slightly conical formats. Among the accessory groups there is an optical system to search for the notch on the bottom of the bottles which guarantees the orientation of the package during the label application phase. The user interface has been completely redesigned: the operator has an 8-inch colour touch screen at his disposal, with which to set the labelling programs and carry out tests and manual cycles, all already set up for Industry 4.0. Last but not least, the footprint of the machine in its full-optional set-up, with dispenser, capsule smoothing, three labelling stations and final collection table is very small, allowing it to be installed even in small spaces.