Customized design, high innovation and flexibility, power and cost-effectiveness, guarantee and very high hygiene standards: we can easily say that the quality granted by ME Food Solution houses in this eight-point “programme”. The real strength, however, generates from the combination of all those crucial elements; that’s the reason why ME Food Solutions’ professionalism is appreciated all over the world, in work environments where food processes are closely controlled.

Customized design, high innovation and flexibility, power and cost-effectiveness, guarantee and very high hygiene standards: we can easily say that the quality granted by ME Food Solution houses in this eight-point “programme”. The real strength, however, generates from the combination of all those crucial elements; that’s the reason why ME Food Solutions’ professionalism is appreciated all over the world, in work environments where food processes are closely controlled.

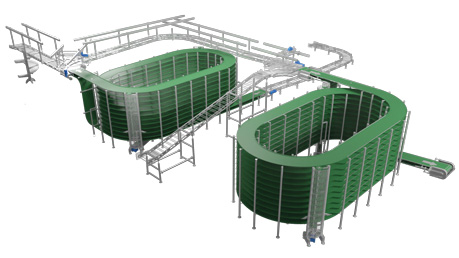

To meet cooling, freezing, pasteurization, leavening and conveying requirements, ME Food Solutions offers patented solutions: spiral systems with external drive (drum-free) that mesh the belt, consisting of a jack chain in stainless steel AISI304 running on lubrication-free tracks by means of FDA-certified technopolymer wings.

Understanding the challenge and providing a safe and performing machine is the request that the Management, Eng. Luca Priore, and his team, welcome every day: experience, design and problem solving are strictly applied to meet customers’ always different production requirements.

ME Food Solutions imbues the design with the same passion, no matter if big-sized or small-sized plants, maybe due to space optimization: the beauty of the “problem” and the merit of the solutions, often to be invented, are the real innovation flywheel that Millennium Engineering puts at every customer’s service.

Is that only theory? And practicality?

Last 21 January 2021, in Hungary, the assembly of a two-spiral system for cooling and freezing, produced for an important company of the bakery sector, was concluded. Several products, such as loaves and round bread, and some tailored solutions with conveyor and lifting bends that activate a by-pass system to guarantee the whole plant utmost flexibility.

The bread out of the ovens has a temperature of about 90°C and gets into a cooling cell of 55 cm height. Then, it will lay for about 45 minutes on a spiral of 236 metres, in a controlled-temperature environment at +15°C, where it will reach a temperature of 25°C.

Colling is followed by freezing, for which ME Food Solutions recommends DLS650EVO: 65 cm wide, 212 metres of useful length, developing in 10 levels. Speed – variable from 2,4 and 7,2 m/min – is coded in 4,8 m/min. The product will remain in the spiral for 45 minutes, enough time for its temperature to be dropped below zero, -7°C.

4 highly flexible conveying systems DLC650 covering more than 30 metres convey the product between the ovens and spirals.

What about the by-pass?

The customer was requiring one single plant, for space streamlining and cost saving, for products that need different processing.

• Cooling and freezing in one line,

• Product cooling and conveyance to packaging,

• Direct product loading for freezing,

• Combined possibility of using the two spirals individually for different products, at the same time.

ME Food Solutions has therefore created “variable routes” thanks to lifting conveyors that activate 4 options of product handling. Machine management, and therefore coding of the “production line”, is by means of a touch screen: the benefit lies on the flexibility of having 4 plants in just 1, to select the best of them in accordance with the production requirements.

For this project in Hungary, ME Food Solutions has also studied special lifting devices for both the conveyor DLC650 and the DLACU bends, with fixed wheeled frames and rack or chain rails, set on the ceiling.

Design, personalization, innovation and flexibility, resistance and cost-effectiveness, proven guarantee, and hygiene policy: with 25 years’ history and excellent results, we can easily say that ME Food Solutions stands out for and is guarantee of “all-in” in food processing, and that’s oil-free.