Pack-Sim: 3D design and simulation of the complete bottling line

Pack-Sim: 3D design and simulation of the complete bottling line

Scanny3D S.r.l. is a highly specialized company that deals with the design and production of reverse engineering systems, in particular 3D laser scanner and CAD-CAM software development for industry. One of the most important sectors, in which Scanny3D products find application, is packaging and bottling.

The PACK-SIM software, conceived and produced by Scanny3D, was developed entirely for the rapid, fully automatic and extremely accurate design of stars and screws for the bottling sector.

The software consists of several modules. The star module is able to simulate up to 3 gripping heights at the same time and guarantees full compatibility of the generated surfaces (exportable in STEP and IGES formats) with the main CAD-CAMs.

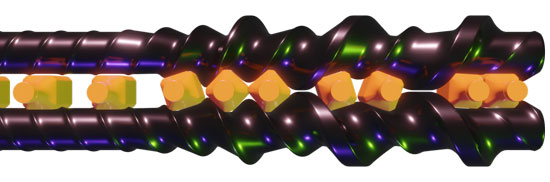

The SCREW module, on the other hand, facilitates the design of 3D screws and counter- screws of any type (transport, rotation, grouping, inversion, singling, etc.) for bottles, flasks and containers of any shape and size. Furthermore, the software allows the design of screws of any type by defining customized motion laws. Through an easy-to-use interface, the software allows the definition of the law of motion of the bottles along the screw with different data entry modes and allows them to be customized in terms of speed, rotation and position of the bottle during handling.

A special function allows the generation of the star in 3D, allowing the automatic creation of the alveoli in 3D to ensure a better adaptation of the lateral surface of the alveolus to the surface of the bottle or bottle. In this way, handling accuracy is considerably increased and correct contact tolerance is ensured even in the case of delicate bottles. The simulation is carried out in a few minutes and allows you to obtain a 3D model of the screw with a perfectly smooth surface ready to be made.

Finally, the multistar module allows the graphic simulation of the entire bottling line.

For Scanny3D, the innovation process has always played a central role and is powered by the constant relationship maintained with customers and their technical feedback on the systems used. The R&D department designs systems that are increasingly accurate, reliable but at the same time easy to use for the end customer, thanks to the use of cutting-edge technologies, especially in the field of 3D.