SMI: even more functional and sustainable packaging

SMI: even more functional and sustainable packaging

Nature plays an increasingly important role in the everyday life of all of us!

Thanks to investments in industrial plants equipped with smart and green technology, like the machines supplied by SMI, food & beverage companies will save on energy, reduce the production environmental impact and use recyclable and biodegradable packaging materials to manufacture packs in film or cardboard.

Future is always full of challenges. SMI solution for competitive market!

The companies influenced by the trend of strong product diversification, need very flexible and efficient bottling and packaging plants in order to reach high levels of optimization and competitiveness of production lines.

Furthermore, in an economic environment that is increasingly oriented towards eco-friendly solutions in the use of plastic packaging, a growing number of companies have chosen to use rPET (100 % recyclable PET) bottles and cutting-edge technical solutions, like those supplied by SMI, in order to save energy and reduce the production environmental impact.

Recent studies clearly show the advantages related to the use of PET plastic bottles, containers that are unbreakable, safe, with great barrier properties, light and above all recyclable. When compared to other packaging materials, like glass or aluminium, traditional PET and, above all, its 100 % recyclable version (rPET), has a good environmental profile, especially thanks to its lightweight, that results in less material to be produced, less material to be disposed of, less energy used to manufacture it and less fuel used for the transport of packed products.

SMI manufactures bottling plants and packaging machines with an innovative design, equipped with IoT technology, providing to its customers, located all over the world, with smart solutions, able to meet their requirements in terms of competitiveness, production efficiency, operational flexibility, energy saving, easy management and monitoring of the whole production process.

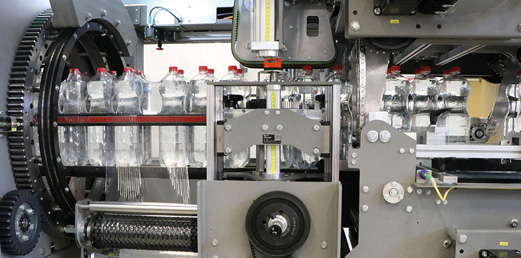

The EBS ERGON series of stretch-blow moulding, available both in “stand alone” version and in “combi” version, integrated with filling and capping systems (ECOBLOC® ERGON series), ensure high performances in the stretch blow-moulding of rPET, and PET bottles of different shapes and capacities from 0.10 L up to 10L mainly used for the food, beverage and detergent industries, able to meet production requirements up to 36,800 bottles/hour.

Thanks to high-tech components, low maintenance and running costs and great quality/price ratio, SMI machines are the best solution for producing plastic containers.

SMI, aware of the challenges posed by this directive to beverage manufacturers, offers solutions for producing containers with a percentage of recycled PET in compliance with 2019/904 and supports customers in order to evaluate the right tethered cap solution.

Green solutions for the primary packaging. Main advantages of EBS series

– compact, ergonomic and functional frame, capable to considerably simplify its running, cleaning and maintenance operations and to ensure significant space saving in the bottling line;

– new preform heating module, characterized by compact dimensions, horizontal frame of the preform-holding mandrel chains (37 mm pitch for the production of bottles up to 3 L) and an optimized ventilation system. The new heating module is equipped with heat-reflecting, high energy efficiency panels made of composite materials positioned both on the front and to the rear of the heat lamps in charge of preforms heating. It ensures a high reflection of the heat generated by the lamps and its more uniform distribution on the preforms surface

– blow-moulding module equipped with motorized stretching rods whose functioning is controlled by electronic drives with no need of mechanical cams. This new technology enables a precise descent of the stretching rod, an accurate control of its position, remarkable energy savings along with a reduced stress generated by the vibrations of mechanical components. Moreover, this new technology enables to adjust the stretch-blowing speed without mechanical interventions (cams replacement)

– high performance, low dead volume valves system which has reduced the pre-blowing and blowing times with the subsequent great advantage in terms of machine’s efficiency and quality of the final bottles

– automation and control by Motornet System®, which ensures the constant keeping of optimal working parameters during the whole production cycle and directly adjusts the machine’s settings, simplifying format changeovers

The advantages of the ECOBLOC® ERGON integrated solutions of blowing-filling-capping.

The ECOBLOC® ERGON series offers the end user countless economic benefits such as:

– modular and compact design, which combines in a single block the stretch-blow moulding, filling and capping modules;

– low consumption of water and energy, thus allowing low running and maintenance costs and safeguarding the environment;

– excellent accessibility and easy maintenance operations;

– automation and control system allowing the management of the system by only one line operator through a simple and user-friendly man-machine interface;

– high precision system, for the application of screw caps and pressure caps;

– cap hopper feeding placed outside the machine at a height easily accessible by the machine operator;

– electronic filling system: no contact between the bottle and the filling valve (in case of still products).

Green solutions for secondary packaging

Within secondary packaging, SMI offers a wide range of automatic machines for packing in an efficient and eco-sustainable way several types of containers with an output up to 450 packs per minute (in triple lane) and applications that ensure energy saving.

Depending on the type of product to be packed and on the reference market, it is possible to choose the most appropriate packer among a wide range of automatic shrink wrappers for secondary packaging in stretch or recyclable film or among packers that use corrugated, kraft or Arcwise® cardboard.

All automatic packers produced by SMI are inspired by Industry 4.0 and Internet of Things (IoT) concepts and ensure cost reduction, energy saving, environmental sustainability and increase in competitiveness.

Interactive tour to discover sustainable solutions

SMI still thinks about all those customers who, due to restrictions related to Covid-19, cannot travel to go to the Italian headquarters or to take part in trade fairs.

In order to find out the advantages of SMI complete lines, customers are invited to access the interactive tour, available on the web site www.smigroup.it: a journey inside two complete line solutions featuring sustainability and compliance with Industry 4.0, that allow to discover the cutting-edge technology to reduce the carbon footprint, energy consumption and waste material.

Flexible market-driven organization

In a global market where competition is getting fiercer and fiercer, the possibility to guarantee a “next door” service is for SMI a key factor to effectively and successfully support customers wherever they are. Thus, over the years SMI has set up a widespread network of branches and representative offices in order to extend the service to the widest number of clients.

In the Asian continent SMI operates through two wholly-owned subsidiary companies: SMI Asia Services Sdn Bhd based in Malaysia and SMI Machinery Beijing Co. Ltd based in China (with offices in Beijing, Nanjing and Guangzhou). Local staff’s expertise and know-how ensure an accurate and qualified support to Asian customers.

About SMI

The SMI Group, one of the world’s largest manufacturers of bottling and packaging plants for production requirements up to 36,800 bottles/hour, has been continuously looking for new technical solutions that adapt to the changing market needs and that ensure customers production performance and ecosystem protection.

The environment has become a common good everyone has to take care of and this objective can be achieved by investing in industrial plants equipped with green technology that allow to save energy and reduce the production environmental footprint.

With 6,800 packaging machines in operation in more than 130 countries, SMI offers a wide range of machines that meet these needs in terms of flexibility and versatility and are able to combine safety, sustainability and innovation.